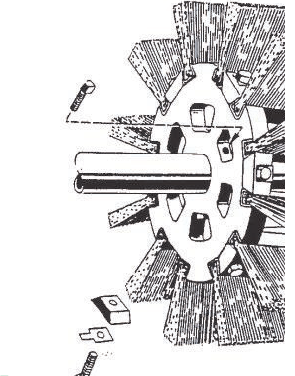

Helical Construction Brush

HELICAL CONSTRUCTION

Industrial conveyor belt cleaning brushes are assembled by fixing heavy duty cage type castings onto a shaft, then fitting 12 metal back strip brushes into the six location spaces giving an overall brush diameter of 305mm. Maximum length of 4000mm long.

- Left or Right hand helical patterns are available.

- Smaller castings also available to give 250mm overall diameter.

This type of construction has the advantage of using heavy duty helically formed strip brushes that can be refilled on site. Open cage type construction is ideally suited where brush clogging causes problems.

- Brush units are usually mounted under the head drum so the rotating brush will sweep residue material away from the belt.

- Independent screw adjustment provides a simple method of brush adjustment.

- Recommended brush speed is 3x belt speed.

BRUSH ADJUSTMENT

The method of brush adjustment on a Helical brush is easily done by an independent screw. This simple method of adjustment independent of conveyor frame, allows a brush movement of 1.5mm for each half turn of the screw.

The brush units are usually mounted under the head drum so that the rotating brush will sweep residue material from the belt to be collected.

Download a brochure here